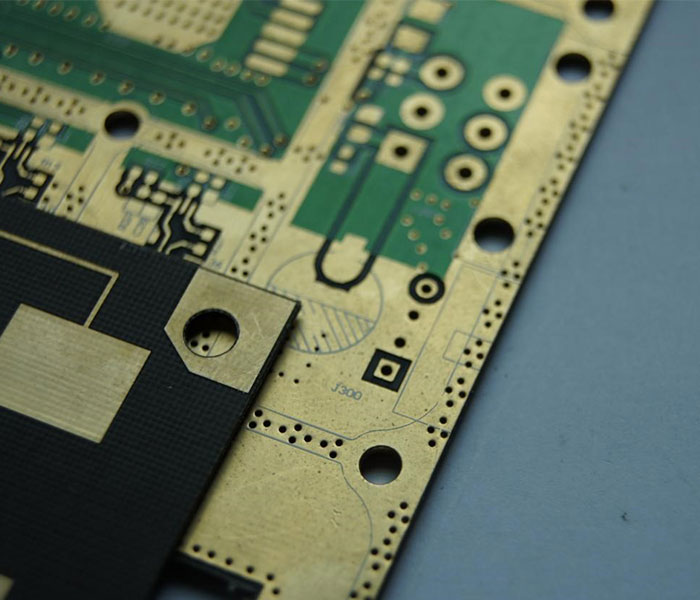

An aluminum printed circuit board (PCB) is a metal-based copper-clad laminate known for its superior performance, boasting excellent thermal conductivity and electrical insulation properties. Among Metal Core PCBs, aluminum PCBs are the most prevalent. These boards typically feature an aluminum layer combined with FR4, also known as 'Flame Retardant 4', which is thermally coated to efficiently dissipate heat.

The heat dissipation performance of aluminum PCBs surpasses that of standard FR4 PCBs.

Aluminum PCBs exhibit stable dimensions, with minimal size fluctuations even under heat.

Crafted from recyclable metal, this product stands as an environmentally conscious choice, contributing to sustainable practices.

Aluminum PCBs rapidly dissipate heat, minimizing potential damage to the printed circuit board.

Aluminum PCBs feature remarkably lightweight metal, offering strength and resilience without additional weight.

A robust and long-lasting product, it minimizes fragility, ensuring optimal lifespan both during and after production.

In hybrid aluminum structures, non-thermal materials undergo separate processing and refinement before being applied to aluminum-based thermal materials.

In the high-performance power supply market, multilayer aluminum PCBs are very common, made from multilayer thermal dielectrics.

When dealing with the most complex structures, single-layer aluminum is backfilled and pre-drilled before lamination to form the core of multilayer structures.