Customer Support

At HuaXing, we believe in providing exceptional customer support to complement our high-quality PCB products. Our dedicated team is committed to your success:

Comprehensive Design Review

Rigorous scrutiny of design for flawless manufacturing.

Advanced Material Inspection

Top-grade materials for unmatched quality.

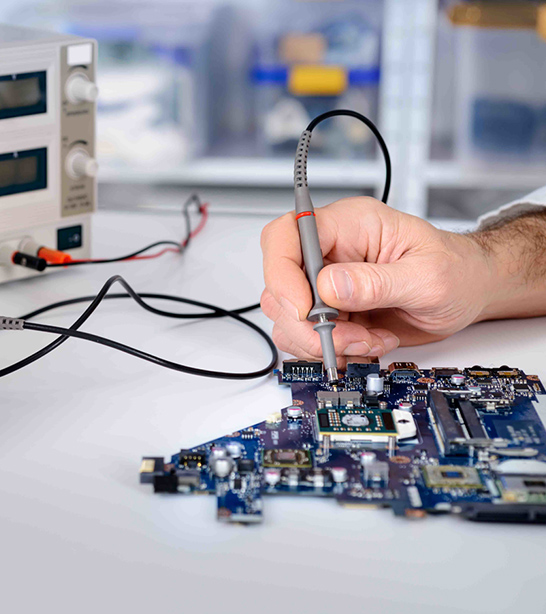

Automated Optical Inspection

Cutting-edge technology for detecting the slightest imperfections.

Thorough Electrical Testing

Ensuring optimal functionality and performance.

Robust Thermal Stress Testing

Proven resilience under extreme temperatures.

Meticulous Physical Inspection

Every detail, scrutinized for perfection.